Differences Between Interior and Exterior Concrete Slabs

If you have a large construction project coming up in the near future, starting to think about concrete services is now.

You want to hire someone who understands different types of concrete, how to correctly manufacture concrete for different applications, and is prepared to go above and beyond to create a high-quality product.

While there are many similarities between preparing concrete for interior and outdoor use, our concrete professionals understand that there are also some crucial variances.

In this article, we’ll learn the difference between interior and exterior slabs with the guidance of choosing one!

What is Concrete Slab?

A concrete slab is a structural element that can be used as a floor or a roof and is typical of constant thickness. The subsoil supports a slab-on-ground structure and is typically reinforced with reinforcing bars or welded wire mesh.

A suspended slab (also known as a structural slab) spans between supports.

It must be strengthened to withstand bending moments estimated from statistics depending on load intensity and span. One-way slabs, two-way slabs, waffle slabs, flat plates, flat slabs, and various additional slab forms are available.

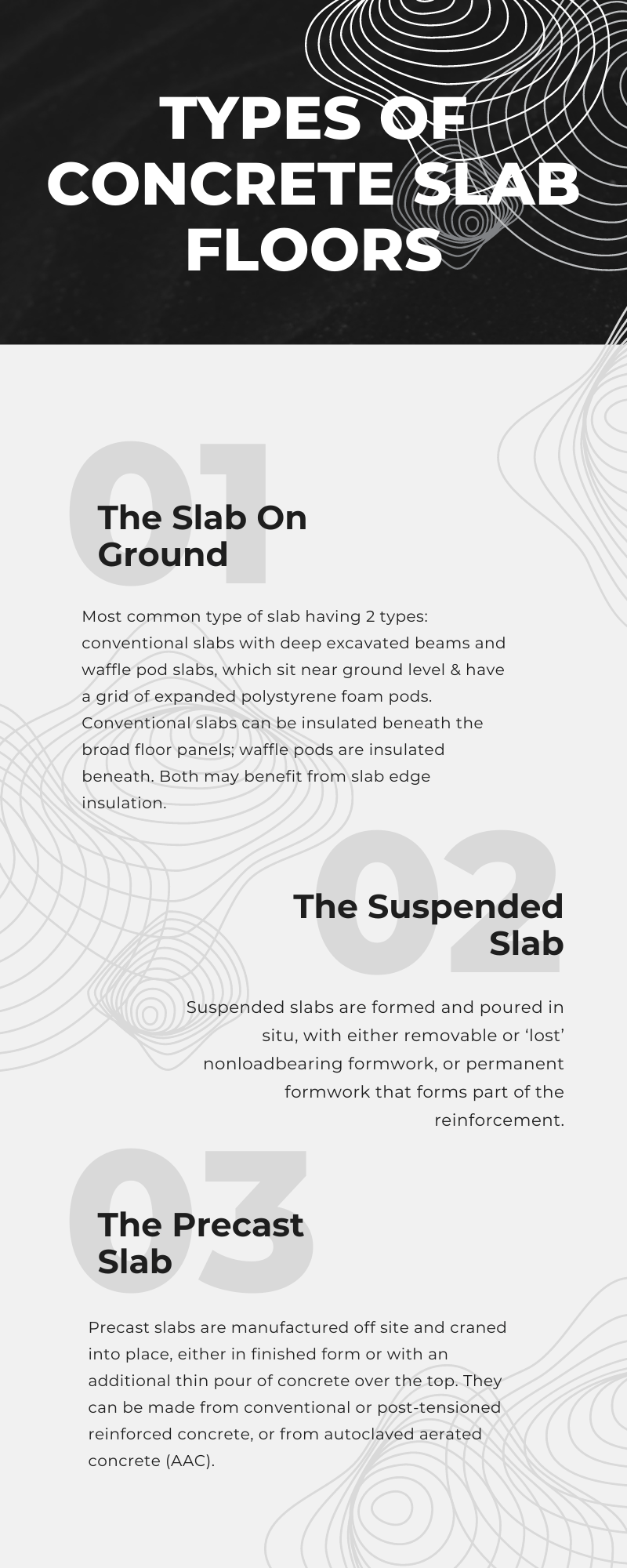

There are also types of concrete slab floors described in the infographics below:

Interior vs. Exterior Concrete Slabs

The weather has a significant impact on the installation, quality, and long-term durability of concrete. Interior concrete slabs are often not exposed to natural environmental changes and often do not require any air entrainment since they are less prone to cracking than outside concrete.

The fundamental distinction remains in the polish of the concrete. Finishing exterior concrete too soon (before the surplus water has a chance to rise to the surface) will trap the bleed water, paving the way for subsequent surface issues. Exterior concrete is typically finished with a "rough broom" texture to provide traction for vehicles and pedestrians, minimizing the possibility of sliding and falling.

Concrete Slabs Formulation

The location of the concrete, whether interior or exterior, influences how the concrete should be mixed for maximum efficiency. Because interior concrete will not be subjected to drastic temperature changes over its lifetime. The formula does not need to be as strong or durable as outside concrete.

The indoor concrete formula does not require air entrainment, although it may have different strength demands. While the formula for outdoor concrete still calls for more sand than cement, the ratios have shifted more in favor of the cement than in the case of inside concrete. Because of this, outdoor concrete formulations will be slightly more expensive.

But the resulting strength and durability will last for years. Using additional cement improves bonding, resulting in a concrete surface suitable for parking lots, patios, sidewalks, and garages.

Concrete Slabs Maintenance

Although its relative strength and durability, concrete has a weakness that can be abused by specific environmental circumstances. Interior and exterior concrete encounter distinct problems that must be addressed if you want your surfaces to last as long as possible.

Concrete surfaces outside of a property, for example, are subject to weather and regional climate. Wind, rain, temperature changes, pests, and grime are common dangers to your external concrete. This isn't to mean that internal concrete surfaces are unaffected. For example, a concrete slab floor must withstand pressure.

Like heavy trucks, daily foot activity tracks dirt, dust, oil, and other debris, moisture infiltration from below the substrate, temperature variations (if not properly climate-controlled), and other factors. Concrete countertops are bound to be subjected to dampness, impact, and scratches.

Concrete Slabs Finishes

The technique for adding an overlay to your concrete will differ depending on whether indoors or outdoors. Indoor concrete, regardless of texture, is best prepared using a grinder to smooth down the surface. Following that, vacuum off the dust residue to prepare for your texture overlay.

The broad temperature ranges for external surfaces can mean that utilizing a grinder will cause harm to your concrete surface. Instead, employ an acid etch to prepare the surface for the overlay by making it more porous. After the chemical etching is finished, you must neutralize the surface and remove any leftover acid before applying the overlay.

If there is no extra texture overlay, the texture of your surfaces will differ between outdoor and inside the concrete. Indoor concrete is often intended for foot traffic and should have a smooth appearance.

Indoor concrete is often polished to a great sheen and coated to provide a good grip and a long-lasting luster. Because it is typically used to create grip for automotive traffic, outdoor concrete is often rougher. A rough broom finish with minor ridges is perfect for achieving this texture for outdoor concrete.

This gives a decent surface for car tires to keep a firm grip and is also suitable for outdoor foot traffic.

Concrete Slabs Protection

No matter where your concrete surfaces are located, they require comprehensive security that considers all the above hazards.

Fortunately, high-quality concrete coatings protect both interior and exterior concrete surfaces while improving their beauty. These coatings and sealers permeate the pores of the concrete, keeping the moisture, debris, and other hazardous impurities from entering, expanding, and harming it.

Coating products come in various varieties, some of which are particularly developed for interior or exterior purposes. These products differ in various ways, but the fundamental difference between indoor and outdoor coatings is the resin, which binds the color to the surface. Exterior coatings use softer resins to withstand more moisture and extreme temperature swings.

But interior coatings use more firm resins, which help protect against scuffs and stains. Exterior coatings are also more likely to contain harmful volatile organic compounds (VOCs) that emit unpleasant scents.

Conclusion

So, while contemplating outside concrete slabs, you should evaluate the criteria for outdoor concrete slabs. On the other hand, an interior concrete slab is intended for basements, garages, and other inside uses. When it comes to concrete floor paint, you have a lot of alternatives.

Our team is perfectly equipped to pour concrete slabs for the exterior or interior of a building. After pouring, our staff will provide years of protection through coatings to both indoor and outdoor surfaces while also giving a variety of alternatives to enhance the beauty of your house.

Call us today to learn more about how we can help!