Hiring a Pool Builder Or Concrete Contractor For Your Pool Deck

If you want to build a new pool deck on your property to make it more pleasant and functional, the first step is to select the correct pool builder or concrete contractor. Choosing an experienced, easy-to-work-with concrete contractor or pool builder helps ensure that the work is successful, cost-effective, and enjoyable.

But, with so many alternatives available, how do you choose the best contractor to install your dream pool deck? You won't go wrong if you follow these helpful recommendations when picking a pool builder or concrete contractor.

Prepare a Plan

It is said that failing to plan is the same as intending to fail. When it comes to pool deck planning and design, it's critical to have a solid strategy in place before hiring someone to build it. You should decide how big the pool deck will be, how much money you have to spend, and where the deck will go. These factors will have an impact on the results of your project. You will undoubtedly appreciate yourself for making a project plan ahead of time.

Choose the Type of Pool Deck

Pool decks come in a variety of styles based on your budget, aesthetic choices, intended utility, and accessible space. It is now up to you to decide the material you prefer and is suitable for your budget. Concrete, wood, and tiles are just a few of the materials you can use for your pool deck.

Generally, concrete is the finest choice for your pool deck if you desire permanence, sturdiness, and little maintenance. You can also choose from a variety of pool deck materials such as wood, tiles, and others. Each pool deck type has its own benefits and drawbacks, so you should be familiar with the features, maintenance requirements, and design options of your desired pool deck type.

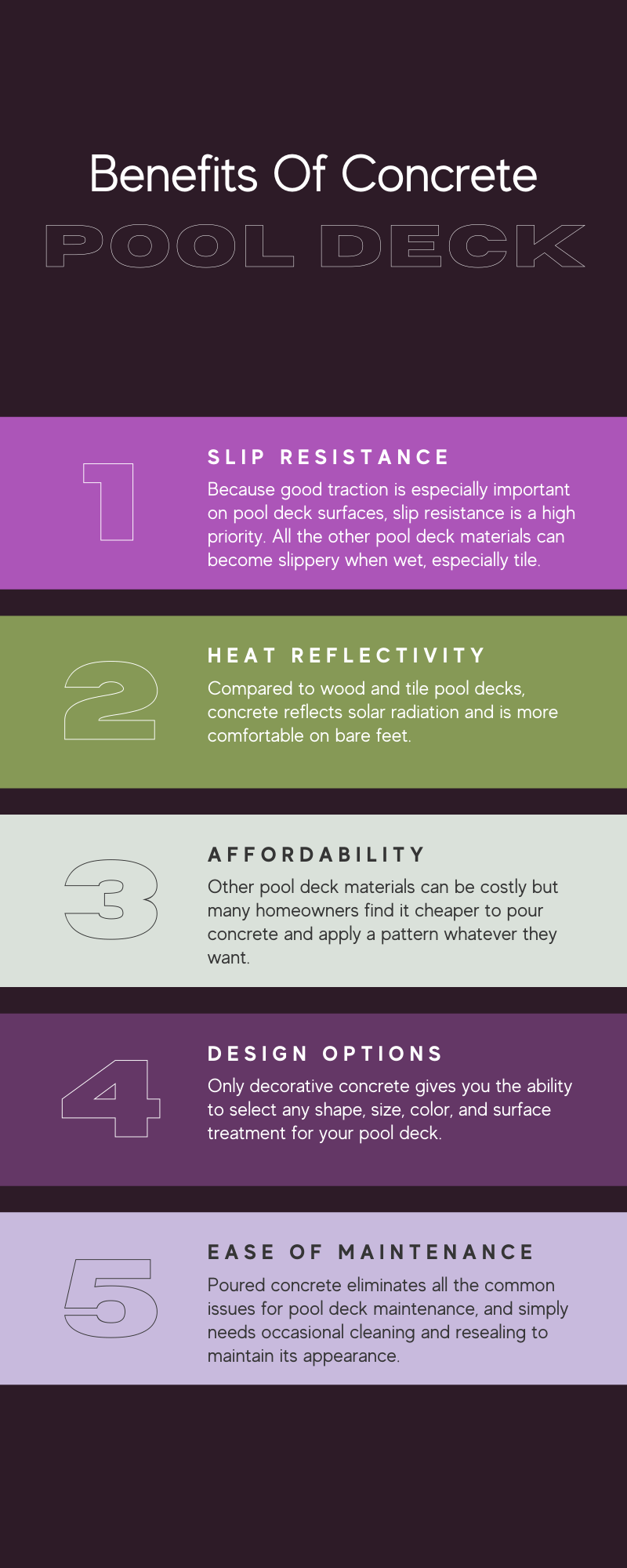

Benefits of Concrete Pool Deck

Create a Defined Budget

Budget is usually an essential consideration in any pool deck construction procedure. Your working budget will be heavily influenced by the type of pool deck you can have, the actual size of the pool deck, the design, and the materials that will go with it. You must calculate the total cost of the pool deck features.

Your budget must be established during the planning process to effectively lead in the other parts of pool deck design and construction. Many competent pool contractors provide free estimates, so get their help if you want a fair price for your pool deck installation.

Check Work Images

Get images of completed pool decks once you've decided on a pool or concrete builder. This will enable you to assess their skills, originality, and overall capability to meet the demands of your project. You may also get suggestions for your personal pool deck layout concerns.

Contractors with considerable pool deck installation experience should be at the top of your list. Their portfolio should include the design and installation of pool decks in both residential and commercial premises. By following these crucial contractor recruiting recommendations, you will undoubtedly locate the most excellent person in the industry.

Ask References

Another diagnostic tool you can utilize is to ask your selected contractor for local references; prior clients have shared their experiences with the contractor's expertise and customer support. Many contractors provide testimonials on their websites, but it's best to ask for previous customers' names and phone numbers for confirmation.

Many contractors hiring guidelines involve this crucial step, so be sure to request some references from your pool contractor to select the best specialist for your pool deck construction.

Speaking with Former Customers

It's also a great step to look at past clients' work completed by a contractor. It is not always possible to speak with customers, although some interesting questions are listed below.

- Did your contractor complete the task on time and on a budget? If not, what was the cause of the overage?

- Were you kept up to date on the charges as they arose?

- How did the contractor deal with setbacks or flaws?

- Were those obstacles or glitches unavoidable? Or did they just appear out of nowhere?

- Was the pool deck builder easy to work with?

- How was the contractor's team? Were they polite?

- Were plans altered while the work was being done, were they accommodated, or was the contractor rigid?

- Would you rehire that contractor?

Get Some Estimates

If you want to ensure that you get the most incredible value and quality for your pool deck installation project, request quotes from at least three to four local companies. When you have many price quotes, you can choose the one with the lowest price or the one that is closest to your budget.

Remember that the cheapest is not necessarily the best, so do your research and seek other excellent features in your desired contractor.

Getting an Estimate from a Pool Deck Builder

- Pool deck estimates should be provided in writing.

- The task to be done should be detailed in writing.

- A pool deck project rendering should be included.

- The precise materials and amounts for the deck should be inventoried.

- A deadline should be set for the work to be finished.

- A cost estimate should be written down.

Create a Predefined Schedule

You must set a specific work timetable for your pool deck construction job. Make sure that your worker gives a schedule as well as progress reports. The contractor must ensure that the project will be completed on time and within budget. Arrange for a discount if the contractor fails to fulfill the timeframe.

Pool Deck Builders Warning Signs

Avoid pool deck builders or contractors who have some drawbacks listed below:

Requires that you must pay the entire amount ahead.- Makes you feel obligated to make an urgent commitment

- Does not have or is unable to present evidence of insurance

- Is not authorized

- Requires you to get the relevant permits.

- Has no other pool decks made in his portfolio

Final Verdicts

Follow these helpful recommendations for hiring a pool builder or concrete contractor if you want to acquire your ideal swimming pool deck at a reasonable price. You will receive not only a high-quality, long-lasting pool deck but also a stylish and slip-resistant pool deck surface.

We offer expert pool deck installation services in your city and the surrounding areas. Call us for a free quote on our unrivaled yet reasonably priced pool deck and concrete installation services.