Commercial Versus Residential Concrete Jobs in El Paso

The two primary operations of the building sector are commercial concrete construction and residential concrete construction. Everyone understands that commercial concrete is concerned with constructing huge commercial buildings. In contrast, residential concrete construction involves building homes and dwelling units. But how to compare them in terms of other aspects of concrete construction?

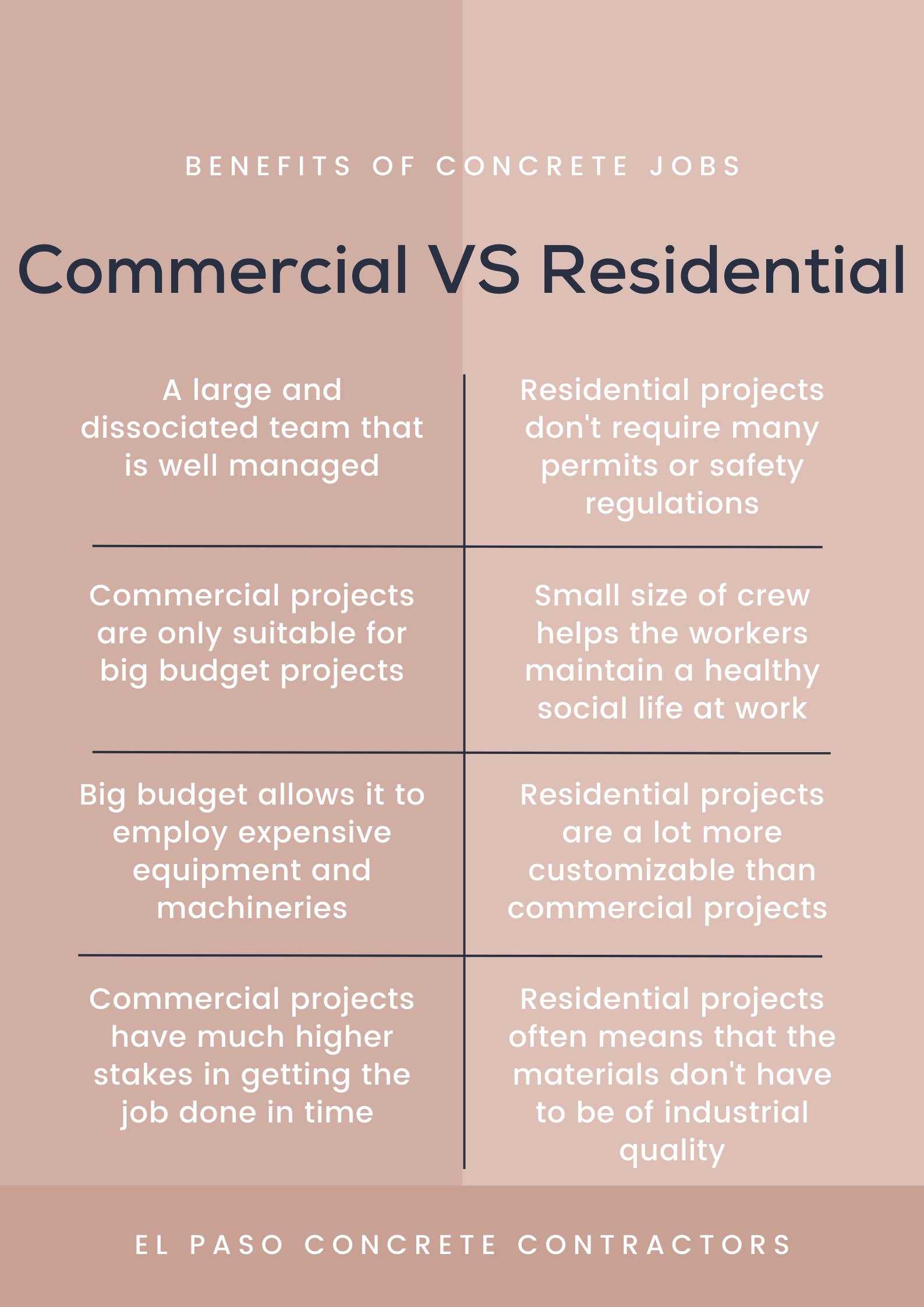

The risks in concrete commercial projects are often more significant than residential construction projects. They have a much more complicated pipeline and a significantly higher overhead. Residential construction is substantially more relaxed in terms of work tempo, permits necessary, and worker closeness.

All of this will be covered in-depth in this post. We'll start with a simple definition of the two forms of concrete construction and some considerations for each. Then we'll do a lot more in-depth analysis.

What Are Commercial Concrete Jobs

Commercial concrete is defined generically as concrete used to construct or improve areas such as industrial buildings, warehouses, retail stores, and even restaurants. Commercial concrete can be found almost anywhere in a structure, including the walls, floors, outdoor walks and pavements, and even design aspects.

Commercial concrete often faces higher expectations in terms of structural performance and longevity than residential concrete. More complex concrete mix designs and greater reinforcing, such as post-tensioned slab construction, are frequently required for commercial concrete floors and pavements.

What Are Residential Concrete Jobs

Residential concrete design and construction entail designing and constructing multi-unit structures such as flats, townhouses, or apartments. On the other hand, the single household is the most generally considered residential building project. Residential concrete construction can also include the refurbishment of existing structures.

Usually, the job is completed by a local General Contractor and a team of employees. Architectural flatwork, foundations, basement walls, concrete dwellings, roads, walkways, patios, pool decks, poured walls and decorative concrete are all examples of residential concrete.

Commercial vs Residential Concrete Cost

Commercial concrete construction is more complicated than a residential job, resulting in greater costs. When examining the differences between commercial and residential projects, you're looking at time and materials in terms of price.

Housing areas require less time since there are fewer people, rules, and work to deal with. A highly complex project often has a higher labor cost to support the strict deadlines and construction. Depending on the overall quantity, difficulty, and labor force required to execute a commercial structure, we can see how commercial concrete construction can be a more costly alternative than hiring a general contractor for residential development.

Materials Used for Concrete Projects

A residential concrete construction industry differs from the commercial concrete construction industry in complexity and scale and in the materials employed. The fundamental distinction is the weight or load-bearing capability of the concrete materials. Commercial structures require significantly greater strength than residential structures since they typically store bigger gear and equipment.

The large-scale nature of commercial concrete construction requires specialty equipment to finish most works. Many commercial concrete construction designs necessitate the use of large machineries such as concrete mixers and concrete pumps. Commercial construction equipment is specialized and to maintain job safety and project quality, these equipment must be handled by skilled personnel.

While concrete residential tasks necessitate specific knowledge, only the most extensive projects require the use of industrial-scale construction equipment. Problems and mishaps on home projects are frequently far more straightforward to correct than those on commercial projects and therefore do not result in as quickly filing a lawsuit.

Project Deadlines

When it comes to large commercial concrete construction, time is money; architects and owners want to finish the project as soon as possible. On the other hand, commercial projects tend to proceed considerably quicker than ordinary house projects due to larger building expenditures and a more systematized process. For companies, faster construction equals reduced labor expenses and a lower overall budget for the project. This encourages commercial concrete contractors to complete their tasks as soon as feasible.

Homeowners tend to make more choices throughout the course of a residential concrete project, which adds time to the project. Home construction teams also have a smaller workforce and frequently work on many tasks at the same time, causing the build to take longer. These considerations, together with the more time-consuming different small tasks, result in a lengthier overall project.

Choosing the Right Company in El Paso

Commercial concrete construction is often faster than residential jobs, although it is more costly and adheres to tighter building rules. On the other hand, residential projects take longer to finish than commercial projects but are less complicated.

The concrete construction company you select to manage your large or small-scale building project should be highly rated and have a proven track record of success in the project.

If you need a residential concrete construction company or commercial construction company to oversee and execute a large-scale project, El Paso Concrete Contractors is a trustworthy company known in the industry for supplying speedy concrete services that never cut shortcuts.