Tips For Coloring a Concrete Slab

Coloring a concrete slab can transform a simple grey surface into a part of a home's décor while also protecting the floor from normal wear and tear. The best pieces of advice for coloring concrete slabs are to completely clean and degrease the floor, ensure there is no moisture in the concrete, treat the surface with an acid etcher, use a suitable sort of color for concrete, and apply two coats of sealer after the floor is finished. Coloring concrete slabs require time and effort, so having enough time to do the project correctly is crucial.

Clean the Surface

A concrete slab must be completely cleaned and degreased before any color can be applied. For this type of cleaning, a variety of degreasers are accessible. Large oil stains on the surface can be partially absorbed by kitty litter before being cleaned off with trisodium phosphate. After cleaning, the floor should be thoroughly rinsed and allowed to dry over several days before coloring.

Check for Moisture

Another helpful piece of advice is to check for moisture in the concrete before coloring it. One method for testing moisture is to tape down many large plastic sheets to the floor, forming an airtight seal. The sheets can be left for 24 hours and then examined for condensation after removing sheets. If there is moisture in the floor, it must be resealed before it can be colored.

Make a Rough Surface

A plain concrete floor must have the right texture before being transformed into a colored concrete floor. Paint will not stick to a smooth and non-porous floor. An acid etcher is a great way to prepare the concrete for painting. The etcher will roughen the surface of the floor, similar to sandpaper, so that color will stick to it. After using the acid etcher, the floor should be thoroughly cleaned and rinsed to guarantee that no acid remains on the floor before painting.

Choose a Proper Paint Type

Painting concrete floors is impossible without the correct paint. There are numerous paints that are suitable for use on concrete. An epoxy-based paint is good for an easy-to-clean surface on painted concrete. Sand can be put into the epoxy to make it more slip-resistant, but it will make cleaning the flooring more hard.

Apply Paint in Layers

Thin, even layers of paint should be placed on the floor. The paint can be applied with a paintbrush, roller, or paint compressor. The paint should be completely dry before applying the next coat. Paint frequently seems lighter in the container than it does on the complete painted concrete floor, so the painter should bear this in mind when putting the paint.

Apply a Sealer

The final stage in painting concrete floors is to seal them. A coat or two of a high-quality sealer will help protect the freshly painted concrete and save money on paint upkeep for years to come. Sealers can be quite unpleasant, so keep the area ventilated adequately while the sealer is applied.

Alternative for Paint

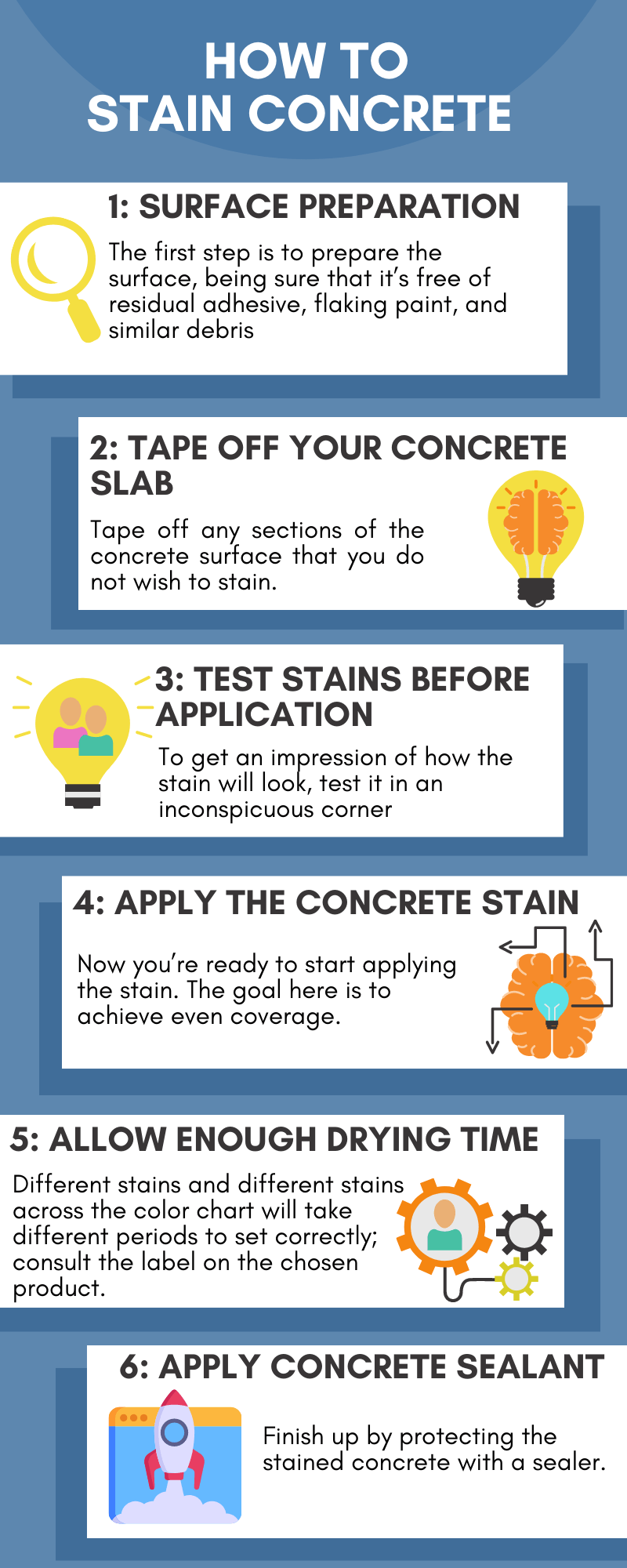

Painted concrete flooring can be replaced with stained concrete floors. The application procedure is nearly identical to painting concrete floors, with the noticeable distinction being that concrete stain is used instead of concrete paint. A coat of wax placed after the sealer is also beneficial for stained concrete floors. When staining concrete, safety clothes such as goggles and gloves should be worn because the stain is far more challenging to remove from other surfaces than concrete paint is.

Afraid of Messing Up Your Floors?

Coloring your concrete floors yourself can be satisfying, but no one claimed it was simple. If you are unsure about your DIY skills, our painting staff would be happy to assist you; we specialize in painting any and all concrete surfaces. Call or email us today to learn more about us and what we do!